Over millennia, nature has perfected the art of biology at the nanoscale. Many of the inner workings of cells naturally occur at the nanoscale.Drawing on the natural nanoscale of biology, Nanoscale materials have far larger surface areas than similar masses of larger-scale materials. As surface area per mass of a material increases, a greater amount of the material can come into contact with surrounding materials, thus affecting reactivity.

A simple thought experiment shows why nanoparticles have phenomenally high surface areas. A solid cube of a material 1 cm on a side has 6 square centimeters of surface area, about equal to one side of half a stick of gum. But if that volume of 1 cubic centimeter were filled with cubes 1 mm on a side, that would be 1,000 millimeter-sized cubes (10 x 10 x 10), each one of which has a surface area of 6 square millimeters, for a total surface area of 60 square centimeters about the same as one side of two-thirds of a 3” x 5” note card.

A simple thought experiment shows why nanoparticles have phenomenally high surface areas. A solid cube of a material 1 cm on a side has 6 square centimeters of surface area, about equal to one side of half a stick of gum. But if that volume of 1 cubic centimeter were filled with cubes 1 mm on a side, that would be 1,000 millimeter-sized cubes (10 x 10 x 10), each one of which has a surface area of 6 square millimeters, for a total surface area of 60 square centimeters about the same as one side of two-thirds of a 3” x 5” note card.When the 1 cubic centimeter is filled with micrometer-sized cubes a trillion (1012) of them, each with a surface area of 6 square micrometers the total surface area amounts to 6 square meters, or about the area of the main bathroom in an average house. And when that single cubic centimeter of volume is filled with 1-nanometer-sized cubes 1021 of them, each with an area of 6 square nanometers—their total surface area comes to 6,000 square meters. In other words, a single cubic centimeter of cubic nanoparticles has a total surface area one-third larger than a football field!

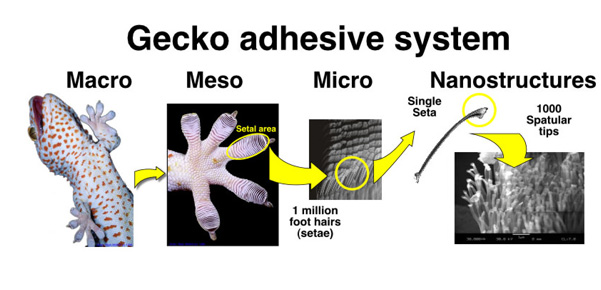

Applying this technology to surfaces has created, Dry glue which is a method of adhesion based upon the naturally occurring adaptations of the feet of geckos. This allows them to climb sheer surfaces, and even glass walls. A variety of synthetic equivalents have been developed, using carbon nanotubes to create synthetic setae on reusable adhesive patches.

A gecko can hang on a glass surface using only one toe. This ability of geckos has been attributed to van der Waals force, although a more recent study suggests that water molecules of roughly monolayer thickness (present on virtually all natural surfaces) also play a role.

In 2007, researchers from the University of Akron and Rensselaer Polytechnic Institute announced they had developed a form of flexible, reusable gecko tape using carbon nanotubes to create microscopic synthetic setae and spatulae capable of supporting supporting a shear stress of 32 N/cm2, which is four times the strength of a gecko's foot. In 2008 researchers from the University of Dayton reported a gecko glue capable of supporting 100N/cm2, ten times the strength generated by a gecko's foot. The research also used carbon nanotubes, but included a curled end which allowed stronger binding but easy removal. Defense Advanced Research Projects Agency (DARPA) has a project called "Z-Man" that is attempting to develop a fabric allowing soldiers to scale vertical walls while carrying a full combat load. In February, 2012 Nitto Denko developed a version of gecko tape capable of sticking at temperatures between -150 and 500°C.

In 2007, researchers from the University of Akron and Rensselaer Polytechnic Institute announced they had developed a form of flexible, reusable gecko tape using carbon nanotubes to create microscopic synthetic setae and spatulae capable of supporting supporting a shear stress of 32 N/cm2, which is four times the strength of a gecko's foot. In 2008 researchers from the University of Dayton reported a gecko glue capable of supporting 100N/cm2, ten times the strength generated by a gecko's foot. The research also used carbon nanotubes, but included a curled end which allowed stronger binding but easy removal. Defense Advanced Research Projects Agency (DARPA) has a project called "Z-Man" that is attempting to develop a fabric allowing soldiers to scale vertical walls while carrying a full combat load. In February, 2012 Nitto Denko developed a version of gecko tape capable of sticking at temperatures between -150 and 500°C.

Physicist and engineer Nicola Pugno, from Turin Polytechnic in Italy, calculated that a person wearing gloves and boots made of carbon nanotubes and structured to mimic gecko feet could indeed cling safely to a wall or a ceiling. Challenges would include wear and tear and the propensity for dirt particles to collect and inhibit stickiness. The suit would have to work on every kind of surface and for long periods of time. But Prof Pugno says: "We are not very far, in my opinion, from a kind of Spider-Man suit." Prof Metin Sitti, from Carnegie Mellon University, says the idea is "not impossible". Selecting a lightweight person and applying the adhesive to many parts of the suit (not just the feet and hands) would improve the chances of success, he explains.

Meanwhile several institutes have been developing robots that can climb walls - Stanford University's "Sticky-bot" can be seen in action here. Some scientists envisage "geckobots" being used to search for survivors in a burning building or disaster zone, to explore the rocky terrain of Mars, or even as toys. But many in the field are most excited by more routine applications.

Medicine is one target area for these adhesives. They could spawn advanced bandages that can be removed easily after healing or gripping surfaces on instruments designed for delicate surgery. Since the mechanism works in the wet, it could be used to affix implants within the body. Stanislav Gorb, from the University of Kiel, studies biological adhesion; his work also looks at the way beetles stick to surfaces. He says gecko material has several advantages when compared with generic sticky tape. There is no "visco-elastic" adhesive to dry out, so it stays attached for longer and leaves no residue. But he says that with current production methods, they are unlikely to replace classical sticky tape.

Synthetic adhesives work best on glass; rough or uneven surfaces pose more of an obstacle. Getting high performance out of gecko material on a variety of surfaces and in different conditions represents the firm's first challenge.Considering nano-technolgy is in its infancy, we are surprisingly finding new uses. A Simple surface area can either turn into a super hydrophobic surface repelling all types of liquids making it self cleaning or in this case a sticky surface with no residue like normal cello tape. It will be interesting in the coming years to see how nano-technology will play through our lives. As we start to understand materials and elements on the periodic table, nano-tech will be adding a new dimension to those same materials. In terms of what we know we are just touching the surface...

No comments:

Post a Comment