Engineers at The Ohio State University have developed super-slick, water-repellent surfaces that mimic the texture of lotus leaves. Scientists have long known that the lotus, or water lily, provides a good model for studying water-repellent surfaces. In studying this leaf, which is covered with microscopic bumps, OSU’s inventors realized that its texture could be exploited in applications where reduced friction is desired, as water-repellent surfaces generally exhibit a low coefficient of friction. The challenge is in optimizing the surface for specific materials and applications, so the researchers developed the first computer model that calculates the optimal distribution of "bumps" on the surface for a particular application. Among the wide range of potential applications, this technology could lead to self-cleaning glass, and could also reduce friction between the tiny moving parts inside micro-electrical-mechanical systems (MEMS), which can’t be lubricated by traditional means.

Engineers at The Ohio State University have developed super-slick, water-repellent surfaces that mimic the texture of lotus leaves. Scientists have long known that the lotus, or water lily, provides a good model for studying water-repellent surfaces. In studying this leaf, which is covered with microscopic bumps, OSU’s inventors realized that its texture could be exploited in applications where reduced friction is desired, as water-repellent surfaces generally exhibit a low coefficient of friction. The challenge is in optimizing the surface for specific materials and applications, so the researchers developed the first computer model that calculates the optimal distribution of "bumps" on the surface for a particular application. Among the wide range of potential applications, this technology could lead to self-cleaning glass, and could also reduce friction between the tiny moving parts inside micro-electrical-mechanical systems (MEMS), which can’t be lubricated by traditional means.Another company based out of Santa Ana called Liquipel, Calif. that specializes in "innovative coatings", claims that they can waterproof your iPhone, and all other electronics, without the use of a case. However, it’s not a product that you purchase, take home and apply yourself. In order to get your phone waterproofed by Liquipel, you would have to send your electronic device to California where the coating is applied. Despite claims of dipping your phone in water for a period of time, some people found that water did leak into the phone. This turned the water indicators inside to turn red, which void the warranty. Self cleaning gadgets of this type might be one thing but still isn't a good idea for people to ignore the warning signs and submerge their phones in water.

NeverWet is a patent-pending silicon-based covering that deflects nearly all liquids and heavy oils by creating a very high contact angle upon application. The angle is much higher than traditional substrates, such as car wax (90 degrees), Teflon (95 degrees), or Rain-X (110 degrees). Liquid literally glides off NeverWet's 160 degree to 175 degree angle in a way that almost seems like computer animation,

At first glance, NeverWet comes across as a liquid repellent, but it is much more than that. Surfaces that are sprayed with NeverWet repel ice, corrosion, and even bacteria. The company behind the product, Ross Nanotechnologies, says on its Web site that the material does not fade in strength from blasts of high pressure. In fact, it even states that NeverWet-infused materials "have remained under seawater for over a year and reemerged completely dry."

The buildup of ice on surfaces can cause problems in many situations: On airplane wings or on their engine turbine blades, ice can both add weight and interfere with a wing’s lift, which can make it impossible to take off; on high-voltage electrical lines, the weight of ice can cause lines to snap, causing blackouts and endangering people nearby; and on structures such as oil-drilling rigs, it can make even basic operations treacherous for people trying to work on slippery surfaces. Preventing these icy buildups usually means using deicing materials (salt or glycol), sprinkled or sprayed on a surface, or activating heating coils embedded in the surface material.

But one such proposed solution — the use of a super-hydrophobic (water-repellent) coating — has been shown by new research from MIT and a team at General Electric to have serious problems. The reason such a coating would not work has to do with frost — ice that forms on a surface directly from a vapor state, or by freezing of condensed droplets. The formation of frost, according to a study published this month in Applied Physics Letters, could completely defeat the water-repelling properties of a surface that normally would inhibit ice buildup — and, in fact, could actually promote ice formation. But the study also suggests that a more complicated, patterned surface might still work.

When super-hydrophobic surfaces are exposed to supersaturated air (such as found in clouds), frost readily forms thus defeating the purpose of the coating. If frost forms, it actually aggravates the problem, because it provides a kind of foundation on which ice quickly can build up to form a thick layer.

Super-hydrophobic coatings cause water to bead up into droplets instead of spreading out across a surface. Many researchers had assumed that the coatings would also prevent ice from forming or adhering to the surface. But in his study, using an environmental scanning electron microscope to study the process.

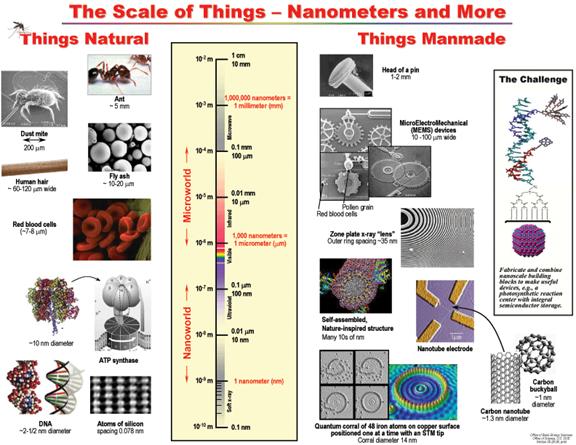

This research, in which they looked not just at how ice and frost form in a stationary situation but also at what happens when the water droplets are moving rapidly before they strike the surface, has pointed to a possible solution. It turns out that certain kinds of complex nano-scale texturing of the surface can drastically improve the hydrophobic qualities, even on a moving surface, by preventing the forming droplets from finding a suitable flat surface to stick to. Getting the size and configuration of these textures exactly right will be the subject of future research. Although recently researchers found, the key to the improved hydrophobic (water-shedding) surface is a combination of microscopic patterning a surface covered with tiny bumps or posts just 10 micrometers (millionths of a meter) across, about the size of a red blood cell—and a coating of a lubricant, such as oil. The tiny spaces between the posts hold the oil in place through capillary action.

This research, in which they looked not just at how ice and frost form in a stationary situation but also at what happens when the water droplets are moving rapidly before they strike the surface, has pointed to a possible solution. It turns out that certain kinds of complex nano-scale texturing of the surface can drastically improve the hydrophobic qualities, even on a moving surface, by preventing the forming droplets from finding a suitable flat surface to stick to. Getting the size and configuration of these textures exactly right will be the subject of future research. Although recently researchers found, the key to the improved hydrophobic (water-shedding) surface is a combination of microscopic patterning a surface covered with tiny bumps or posts just 10 micrometers (millionths of a meter) across, about the size of a red blood cell—and a coating of a lubricant, such as oil. The tiny spaces between the posts hold the oil in place through capillary action.Super hydrophobic properties have far reaching applications in medicine, in aircraft and vehicle surfaces, and also in clothing and other self cleaning surfaces. Nano technology brings a new dimension to material science, as moores law suggest technology will shrink down. We will become aware of manufacturing materials not only for strength and durability but also its surface and interactions with other materials. Superhydrophobic is just one aspect of nanotechnology, considering that recently we only scratch the surface...

No comments:

Post a Comment